Contamination checks take pills for vast improvement

A team of chemical engineers is working on a way to reduce an entire water safety testing lab into a single pill.

A team of chemical engineers is working on a way to reduce an entire water safety testing lab into a single pill.

Researchers want to improve the efficiency and effectiveness of water quality testing by shrinking the process and taking it to the field.

The project was prompted by an everyday invention – reapplying the same material used in dissolving breath strips.

The idea occurred to team member Sana Jahanshahi-Anbuhi, a PhD student in Chemical Engineering at McMaster University, who realised the breath strips could have broader applications.

A team has now created a way to store precisely measured amounts of enzymes and other active agents in pills made from the same naturally occurring substance used in breath strips, putting lab-quality science within instant and easy reach of people who need quick answers to questions such as whether their water is safe.

The technology is expected to have significant public health applications for testing water in remote areas and developing countries that lack testing infrastructure, for example.

The material - called pullulan - becomes a solid when dry, protecting sensitive agents from oxygen and temperature changes that can render them useless within hours.

Until now, such agents have had to be stored at extremely low temperatures - shipped in vials packed in huge chunks of dry ice, at great cost and inconvenience. Using them has been awkward, unwieldy and wasteful.

“This is regular chemistry that we know works but is now in pill form,” says John Brennan, director of McMaster’s Biointerfaces Institute, where the work took place.

“The user can be anybody in a village somewhere who can take a pill out of a bottle and drop it in water.”

The new method, described in an article published online in the prestigious European chemistry journal Angewandte Chemie, also holds promise for other applications, such as packaging that could change colour if food is spoiled.

“Can you modify packaging so it has a sensor to tell you if your chicken has gone off?” Brennan asks.

“The reason that doesn’t exist today is because there’s no way you can keep these agents stable enough.”

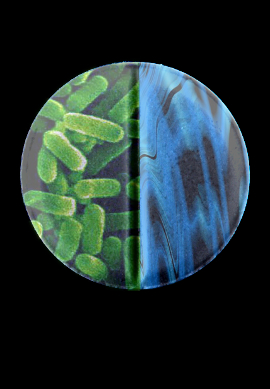

The new method allows the same materials to be stored for months inside tiny pills that dissolve readily in liquid. Pills are inexpensive to produce and anyone can add them to well water, for an instant reading of pesticides, e. coli or metals, or other potentially dangerous materials.

Pullulan is already approved for human consumption around the world, and the researchers say the other steps in the pill-making process can be scaled up for easy commercial production.

A finished product is expected soon.

More details are available in the following video;

Print

Print